Food Processing

We offer proprietary technologies and expert support to help food and beverage manufacturers detect and eliminate biofilms, pathogens and spoilage organisms across diverse production surfaces.

Experts in Biofilm

Our top priority is to help you eliminate foodborne pathogens, enhance food quality, and ensure food safety. We provide cutting-edge chemical solutions that attack and kill bacteria in their natural habitat — biofilm.

Our team provides unmatched expertise and comprehensive food safety support, crafting effective solutions for food processing facilities.

The Sterilex Difference

Our products are recommended by top food safety experts and mandated by some of the biggest names in the industry for use in numerous corporate-wide food processing sanitation programs.

Remove biofilm and kills biofilm bacteria

Patented chemistry penetrates and collapses the biofilm structure, effectively killing biofilm bacteria and removing biofilm from surfaces.

Control pathogens

EPA-registered sanitizers + disinfectants offer comprehensive efficacy against pathogens such as Listeria, Salmonella, E. coli, Cronobacter, Campylobacter, etc.

Reduce cross-contaminations risks

Proven to kill 99.9999% of bacteria and control the spread of pathogens between treated surfaces and hygienic zones.

Reduce risk of recalls + increase shelf life

Eliminate biofilm and kill spoilage microorganisms to ensure a cleaner production environment and prevent repopulation on treated surfaces.

Improve operational efficiency

Save time, labor, chemical, equipment and water with PerQuat Technology

Applications

Sterilex solutions can be used in a variety of applications – providing outstanding microbial control and prevention, optimizing operations, reducing costs and promoting environmental stewardship.

Drains

Eliminate biofilm bacteria and odors that thrive in drains – all without hand scrubbing.

Food Contact Surfaces

Reduce product recall risk + protect your brand with unmatched biofilm kill and removal for one of the most critical surfaces in food facilities.

Environmental Disinfection

Seek + destroy biofilm and reduce cross-contamination risks in areas outside of Zone 1 to keep pathogens away from food and food contact surfaces.

Floor Sanitization

Clean and sanitize floors in one step and reduce cross-contamination across your facility floor—without pausing production.

Entryway Pathogen Control

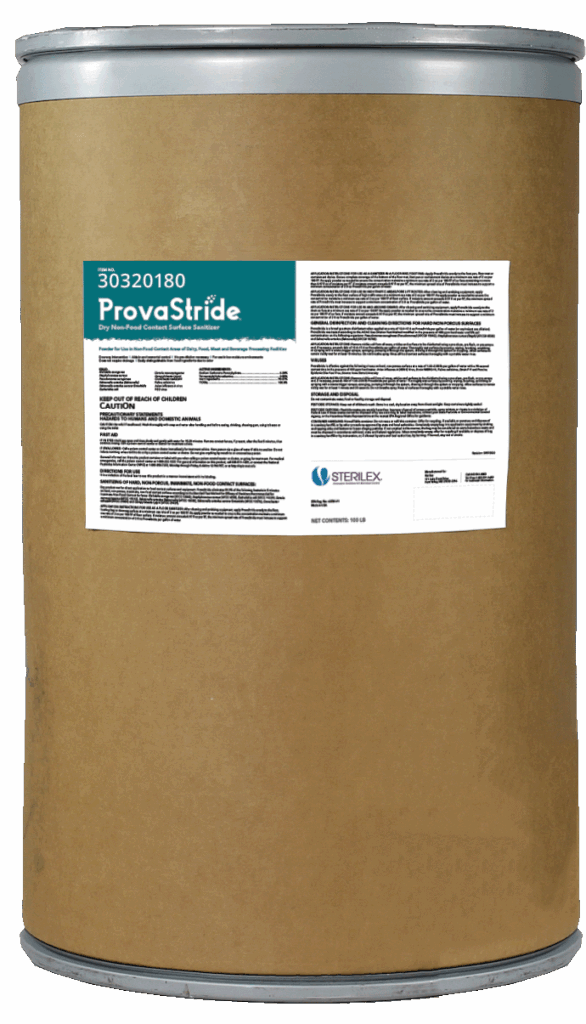

Sterilex dry sanitizers provide extra protection as a doorway intervention on floors, in floor mats and foot pans.

Click an Application above to learn more.

Markets

We are a total food safety solution provider. Our products effectively eliminate foodborne pathogens, enhance food quality and ensure food safety across all food and beverage markets.

Beverage

Dairy

Dry Processing

Frozen Food

Protein

Produce

Ready-to-Eat

Seafood

Featured Products

Discover our best products developed for your industry or application.